LATEST DESIGN IN EVERY SHREDO'S SHREDDERS

SHREDO waste size Reduction Solutions is builds to handle the many Applications:- The SHREDO Shredder Components are manufactured and engineered in such a manner that they are capable to handle various kinds of rigorous operations easily and also ensure the consistent performance for years to come. Various SHREDO Components ranging from fabricated steel base to hexagonal Mulcher shafts all ensure reliable performance.

Waste Product Destruction:- No matter whether it is grimy or old, discarded or recalled stuff, these robust and capable our shredders wipe out all of your unnecessary used material. The package with or without Shrink/wrap any sort of paperboard, wood, drum, glass metal and plastic etc.

Waste Material reclaims:- The main purpose of using our shredders is to recycle the ruined or imperfect items that can be used again In the latest recycling process these components have extracted the dry granular material without much grime from the flawed cardboard containers. Furthermore additions applications for recovery is various contents like liquid, clinical, solid, chemical, tobacco and cosmetic products etc.

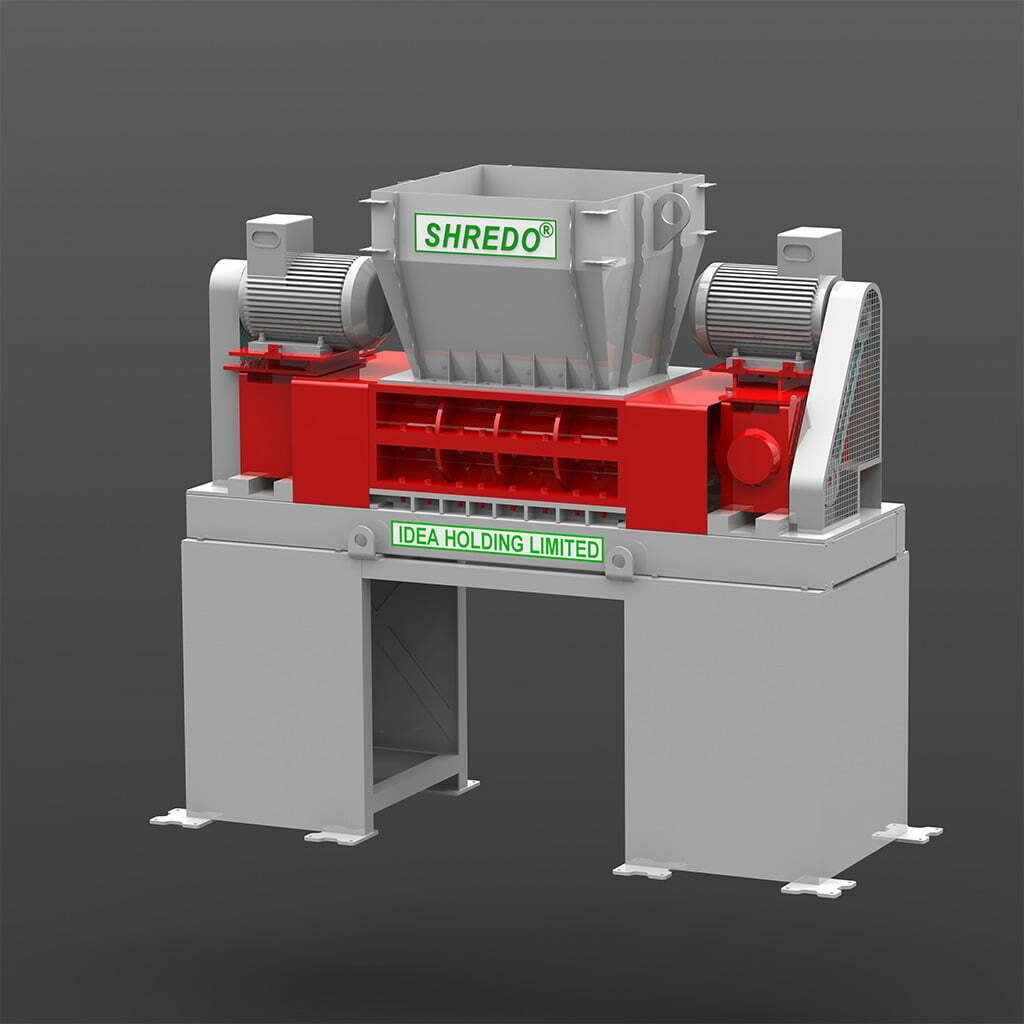

SHREDO’s SHREDDERS:- IHL manufacture a full line of double shaft shredders in order to complete the certain operation necessities such as cutback in size, damaging the material to change the size of grimy for more advancement. IHL offer consistent and capable shredder models for the demands of different range of items from less size/small item to bigger size/huge items.

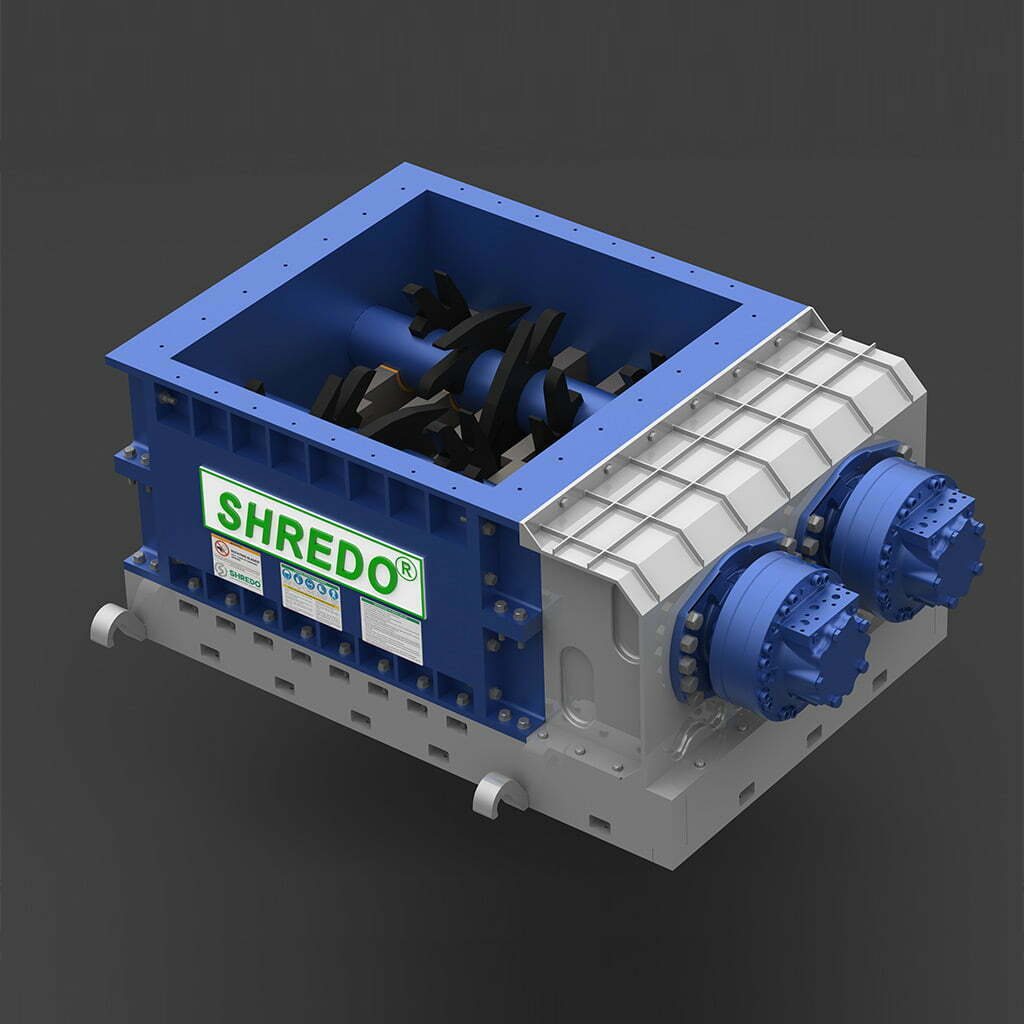

Mulcher Shear Assembly:- SHREDO Mulchers are manufactured from High alloy heat treated processed steel to increase the product life span. The operations and product features decide the Mulcher design including width of Mulcher, hook reach and count of hooks. The location of the Mulchers in the cutting chamber can also be adjustable. This is done in the purpose to achieve the optimal "rip-shear performance and the final product size.

Waste Product Destruction:- No matter whether it is grimy or old, discarded or recalled stuff, these robust and capable our shredders wipe out all of your unnecessary used material. The package with or without Shrink/wrap any sort of paperboard, wood, drum, glass metal and plastic etc.

Waste Material reclaims:- The main purpose of using our shredders is to recycle the ruined or imperfect items that can be used again In the latest recycling process these components have extracted the dry granular material without much grime from the flawed cardboard containers. Furthermore additions applications for recovery is various contents like liquid, clinical, solid, chemical, tobacco and cosmetic products etc.

SHREDO’s SHREDDERS:- IHL manufacture a full line of double shaft shredders in order to complete the certain operation necessities such as cutback in size, damaging the material to change the size of grimy for more advancement. IHL offer consistent and capable shredder models for the demands of different range of items from less size/small item to bigger size/huge items.

Mulcher Shear Assembly:- SHREDO Mulchers are manufactured from High alloy heat treated processed steel to increase the product life span. The operations and product features decide the Mulcher design including width of Mulcher, hook reach and count of hooks. The location of the Mulchers in the cutting chamber can also be adjustable. This is done in the purpose to achieve the optimal "rip-shear performance and the final product size.

Automatic Reversal while Overload:- While in system overloading process Shredders are provided with an automatic security system that pauses and reverses the shredding operation automatically. The shredder incorporated of this system empties itself by own and further automatically sustains the shredding action.

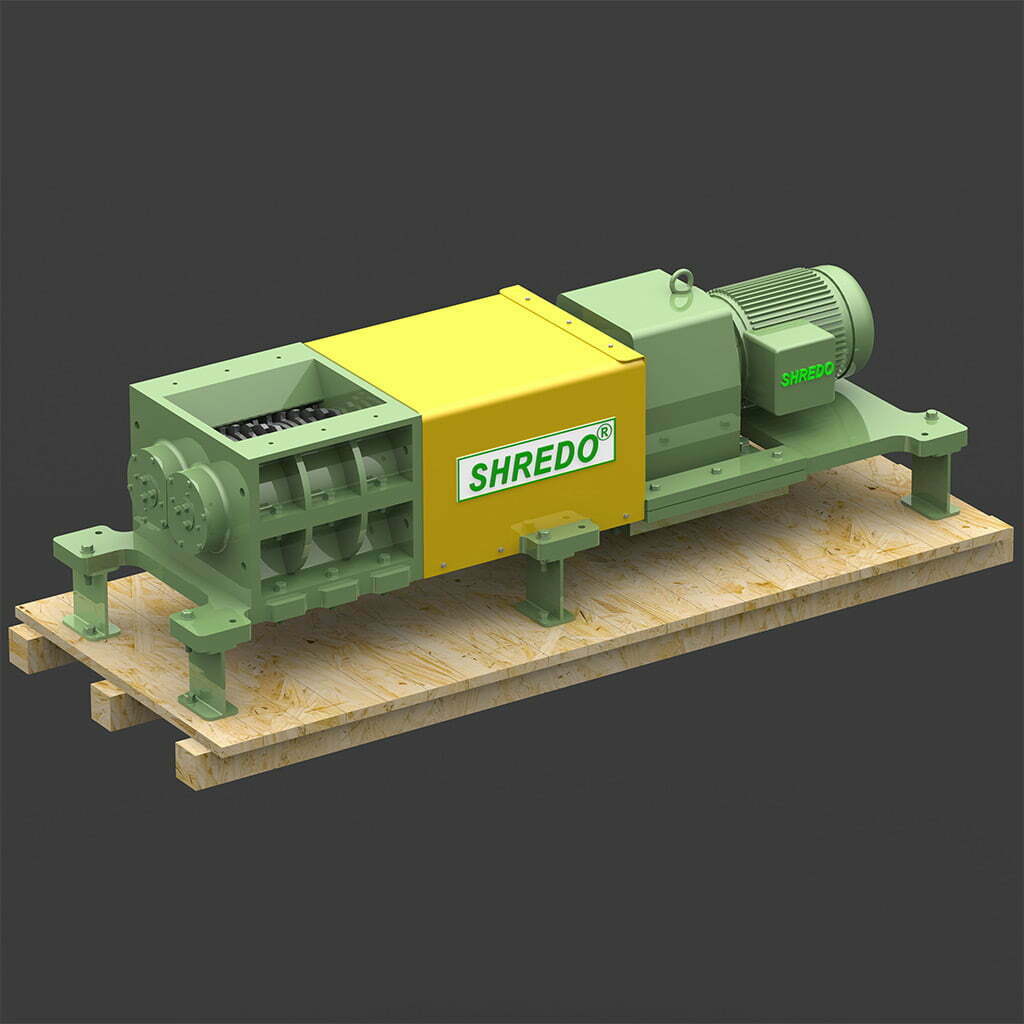

Cost-effective:- SHREDO shredders are constructed in such a way that they require lesser maintenance and provide more efficient performance while possessing with low speed high torque electromechanical drive and an exceptional chopping design

Trouble-free Operation:- Shredder consists of various electronic characteristics like reverse start to automatic cleansing of Mulchers assembly.

Noise free:- The shredders are capable to perform action at low speed while high torque and without producing grime.

Easy Installation:- Comprising with modular design our machine covers up less space in the functional region.

Minimum Maintenance:- Shredo is constructed by using efficient parts, substantial design and others parts which enable them to produce flawless results and ensuring the longer consistency.

Double Gearbox driven, hexagonal/Square Mulcher shafts are architected for additional consistency and recourse by Spherical roller bearings.

Customized Systems with Control:- In case the products require an exclusive system due to their quantity and certain features then the system is comprised of middle sized shredder that works at low speed and huge torque. Then the shredding process begins to minimize the content into equal strips. The conveyor takes up the content to cutting hog working at large speed and converting the content into specific bit size. This machine is constructed in order to minimize and retrieve rubber piece that is produced from components given by the producer for the automotive trade. Each machine incorporates the control lagle that controls the ente functionality of machinery.

Material test facility prior to dispatch:- We have specialized team of engineers that will analyze your stuff to determine the shredding machine required to satisfy your needs.

Cost-effective:- SHREDO shredders are constructed in such a way that they require lesser maintenance and provide more efficient performance while possessing with low speed high torque electromechanical drive and an exceptional chopping design

Trouble-free Operation:- Shredder consists of various electronic characteristics like reverse start to automatic cleansing of Mulchers assembly.

Noise free:- The shredders are capable to perform action at low speed while high torque and without producing grime.

Easy Installation:- Comprising with modular design our machine covers up less space in the functional region.

Minimum Maintenance:- Shredo is constructed by using efficient parts, substantial design and others parts which enable them to produce flawless results and ensuring the longer consistency.

Double Gearbox driven, hexagonal/Square Mulcher shafts are architected for additional consistency and recourse by Spherical roller bearings.

Customized Systems with Control:- In case the products require an exclusive system due to their quantity and certain features then the system is comprised of middle sized shredder that works at low speed and huge torque. Then the shredding process begins to minimize the content into equal strips. The conveyor takes up the content to cutting hog working at large speed and converting the content into specific bit size. This machine is constructed in order to minimize and retrieve rubber piece that is produced from components given by the producer for the automotive trade. Each machine incorporates the control lagle that controls the ente functionality of machinery.

Material test facility prior to dispatch:- We have specialized team of engineers that will analyze your stuff to determine the shredding machine required to satisfy your needs.