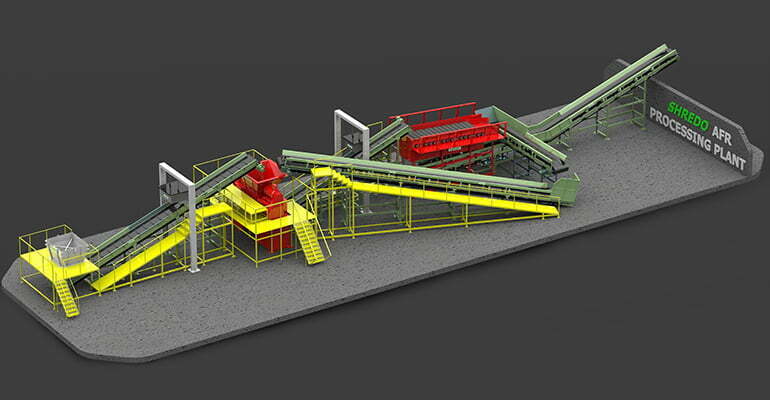

AFR Processing Plant

The SHREDO's AFR Processing Plants are manufactured and engineered in such a manner that they are capable of shredding any kind of AFR available like MSW/RDF, Paint Sludge, Tyre, Plastic waste, Agro- waste, Textile waste, FMCG waste, Industrial waste, Rubber, Plastic Drums, Soft-drink Cane, Pharmaceutical waste, Wood waste, E-waste etc. in single Processing Plant.

Effective Waste Product Destruction: No matter whether it is grimy or old, discarded or re-called stuff, these robust Processing Plants are capable of wipe out things smoothly. These plants are capable of giving output in very small size in 3D with output capacity range from 100TPD to 500TPD or as per requirement.

Effective Screening Arrangement: Screening arrangement is synchronized with both Primary and Secondary Shredder to provide fine shredded output material under specified capacity, also lumps screening is possible with our incorporated system.

Cost Effective: The complete SHREDO's AFR Processing Systems are constructed in such a way that they require lesser maintenance and provide more efficient performance.

- Feeding Hopper

- Feeding Conveyor

- Electro Magnetic Separator for Feeding Conveyor

- SHREDO Shredder

- Electro Magnetic Separator for output Conveyor

- Output Conveyor

- Disc Screen/Separator/Trommel

- Fine Shreds Transfer Conveyor

- Oversize Shreds Transfer Conveyor 10. Oversize Shreds Feeding Conveyor

More Over Plant Consists Features Like

- Robust Shredding Machine

- Noise free working

- Top Quality Conveyor Belts

- Incorporated Magnetic Separation

- Easy Installation

- Ensure Fine Size Output

- Minimum Maintenance

- Auto Reversal to Avoid Jamming

- Less Space requirement

AFR Processing Plant

Alternative Fuel and Raw Material (AFR) Processing Plants are facilities that are designed to process non-recyclable waste and turn it into a source of energy or raw materials. The waste that is processed by AFR plants is typically too contaminated or too difficult to recycle, and would otherwise be sent to a landfill or incinerated. However, with the help of AFR processing plants, this waste can be converted into a useful resource.

How does an AFR processing plant work?

The process of AFR processing plants involves several steps, including:

1. Waste reception: Non-recyclable waste is delivered to the AFR processing plant and sorted according to its composition. This helps to ensure that the waste is processed in the most efficient way possible.

2. Pre-treatment: Before the waste can be processed, it needs to be pre-treated. This involves shredding the waste and removing any contaminants or non-combustible materials.

3. Processing: Once the waste has been pre-treated, it is sent to the processing stage. During this stage, the waste is converted into a fuel or raw material that can be used in other processes. Depending on the type of waste being processed, this may involve gasification, pyrolysis, or another type of conversion process.

4. Quality control: Before the fuel or raw material can be used, it needs to be tested to ensure that it meets the required standards.

5. Transport: Once the fuel or raw material has been processed and quality tested, it is transported to its final destination.

Benefits of AFR processing plants

AFR processing plants offer several benefits, including:

1. Reducing waste: By processing non-recyclable waste, AFR plants can help to reduce the amount of waste that ends up in landfills.

2. Creating a source of energy: AFR processing plants convert waste into a source of energy, which can be used to power industrial processes or generate electricity.

3. Reducing greenhouse gas emissions: By converting waste into a source of energy, AFR plants can help to reduce greenhouse gas emissions that would otherwise be produced by incinerating the waste or by using fossil fuels to power industrial processes.

4. Reducing reliance on fossil fuels: AFR processing plants can help to reduce the world's reliance on fossil fuels, which are a finite resource.

5. Supporting a circular economy: AFR processing plants support a circular economy by turning waste into a useful resource.

In conclusion, AFR processing plants are an important tool for managing non-recyclable waste and turning it into a useful resource. By reducing waste, creating a source of energy, and reducing greenhouse gas emissions, AFR plants can help to create a more sustainable future. As the world continues to generate more waste, the role of AFR processing plants will become increasingly important in managing this waste and creating a more circular economy.