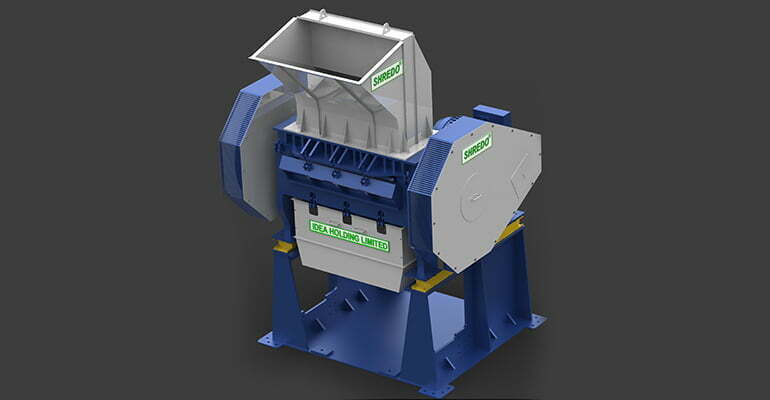

Rasper/Granulator

With sincere intentions to expand our business all across the globe, we are engaged in putting forth the best quality array of Tyre Granulator. The offered is manufactured with the use of premium quality components and highly advance techniques. These Granulator designed to process scrap Tyres for recycling and re-purposing for a variety of applications. Widely used to make tyre granules of different kinds of Tyres. Beside all, our clients can purchase these Granulator at highly competitive prices from us.

Features:- Rasper/Granulator

- Less Wearable Knife

- High Productivity

- Less Maintenance

- Hydraulically Operated

- Low Operation Cost

- Easy Knife Removable

- Robust Construction

- Inbuilt Screen / Mesh

Rasper and granulator machines are essential equipment used in various industries to process waste materials, such as plastic, rubber, and other industrial materials. In this article, we will explore the benefits of using a rasper or granulator machine, how it works, and why it is an important tool in waste management.

What is a rasper or granulator machine?

A rasper or granulator machine is a type of equipment used in waste management to process various materials. The machine uses sharp blades or granulators to shred materials into small pieces that can be used for recycling or other applications. The rasper machine is typically used to shred larger materials, such as rubber and plastic, while granulators are used for smaller materials, such as electronic waste.

Benefits of using a rasper or granulator machine

1. Recycling: One of the primary benefits of using a rasper or granulator machine is that it can help to recycle waste materials, reducing the amount of waste that ends up in landfills or oceans.

2. Cost-effective: By shredding materials into smaller pieces, rasper and granulator machines can reduce the cost of transportation and storage of waste materials.

3. Versatile: Rasper and granulator machines can be used to process a wide range of materials, making them a versatile tool for waste management.

How does a rasper or granulator machine work?

A rasper or granulator machine works by using sharp blades or granulators to shred materials into smaller pieces. The machine is typically fed with waste materials, which are then shredded into small pieces. The shredded material is then sorted and processed into various products, such as recycled materials or fuel.

Why is a rasper or granulator machine an important tool in waste management?

Rasper and granulator machines are important tools in waste management because they can help to reduce the amount of waste that ends up in landfills or oceans. By recycling waste materials, these machines can help to reduce the environmental impact of waste disposal. They are also cost-effective, as they can reduce the cost of transportation and storage of waste materials.

In conclusion, rasper and granulator machines are essential tools in waste management. They can help to reduce the amount of waste that ends up in landfills or oceans, while also being cost-effective and versatile. By using a rasper or granulator machine, waste materials can be recycled and used for various applications, contributing to a more sustainable and efficient waste management system.